Rebuild of “Sure Betts” – Haines 565C

Old School Classic, into Modern Day Weapon

We have had some major rebuilds towed out of Tidal HQ this year for new clients, best of all we can now call them good mates. We were very fortunate to be given the chance to rebuild some old school classics, from Haines Hunters to Pacemakers, all rebuilt with only the best of materials.

One build that really got us excited was the Yellow Haines Hunter 565C, the owners who are keen spearfishes and don’t mind deep drop fishing, wanted a simple clean rig with low maintenance and decent fuel capacity.

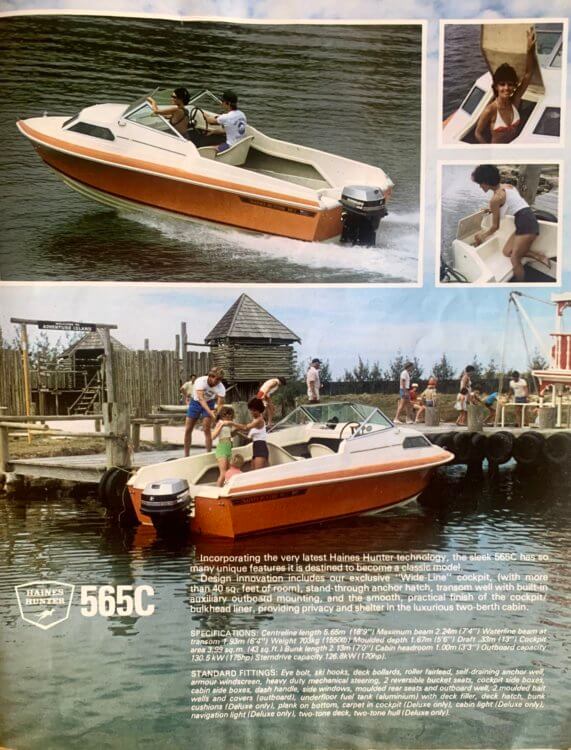

The 565C was always referred to as the ‘Ugly Duckling’ of the range, as Haines Hunter built this hull in an L version which was a low profile cabin; the R version a runabout; and the C version a centre console. Designed in the late 70’s by John Haines, this hull quickly grew a cult following and still does today. The hull is highly sort after and fetches high prices which most resort to as ‘Haines tax’.

Some basic specifications:

Centreline length: 5.65m (18.9ft)

Maximum Beam: 2.24m (7.4ft)

Weight: 703kg

Engine HP 175

“Sure Betts” turned up on a flatbed truck from Dampier, after it was unloaded, we jumped in looking at the floors that had been redone by others and the huge aluminium plate that braced the transom.

The request was to build her like our Tidal Flare, clean, simple, and strong to take a 300 Hp outboard. Once the hull was gutted of its floors, seven stringers and transom, we went through and made sure there were no areas of the hull shell that had major stress cracks and required further grinding and laminating. Not wanting to build a heavy laden hull with more laminates through the hulls running surface we took another approach:

- We laid stitch cloth in the strakes and then filled them with a custom bog mix and laminated over the top;

- 19mm thermolite was used for the stringers bridging the laminates in to one another, and also the bulkheads;

- 38mm for the transom;

- 15mm for the floors all encapsulated in vinylester resin and stich cloth;

- Foam filled the hull;

- The fuel tank with a capacity close to 300 litres was moved forwards 900mm to help with centre of gravity due to a 300 Optimax and the aid of a 5 inch hydraulic jack plate.

- Built in a small kill tank aft of the fuel tank in the hull.

When it came to the transom layout it was undecided, with many calls and pictures backwards and forwards for ideas. As the build was ready for the transom design the owner mentioned a pod (we cringed), and we suggested thinking outside the square and to go with a transom door, something different to all other 565 rebuilds.

We uncovered the Tidal Flare deck mould, and laid up the transom section. Once the part was cured, we demoulded and then had to cut and shut the part on the starboard side to graft it in to the 565C deck, the door on the port needed minor tweaking as well.

After many discussions with the owner, the decision was made to cut the front cabin off and build a custom top deck. We built frames which were nailed and screwed into place, this gave us the basic shape then laid the foam on top and laminated it to hold shape. Once cured the foam was removed and we laminated the underside, with grinding around the edges to strip the deck on and we were ready to glass in to position. Not being a fan of gunnel rubbers, we suggested to laminate the hull deck join and cut the flange off, then put a nice modern alloy gunnel strip in place of the gunnel rubber.

Nearing Christmas, we had limited time and made the call and quickly built a thermolite wave breaker. Before we knew it, the owners were on the way down from Dampier and we were completing fitout. We made the deadline and managed a few water tests off Hillary’s and on the Swan River with a few cold beers. Testing was conducted with 200 litres of fuel and 3 adults, running a 23 Trophy prop “Sure Betts” cruised effortlessly at 28 knots at 4000rpm and topped over 53 knots on her first sea trial, and with few more modifications we will see better numbers. Unfortunately, due to time constraints we didn’t get to weigh her.

In 2020, we will focus on the Tidal range. We suggest if anyone is looking for custom rebuilds, don’t leave it too late and give us a call to lock in a date!